THERMAL BREAK PROFILE KNURLING MACHINE

THERMAL BREAK PROFILE KNURLING MACHINE:

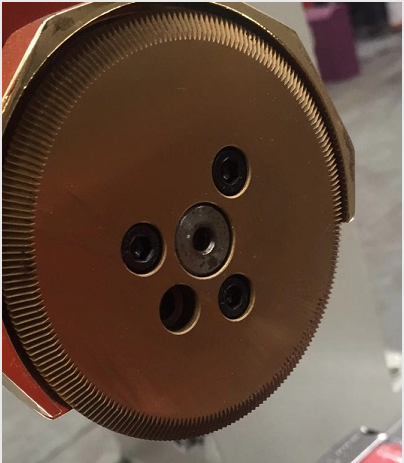

1, long time use knurling knife

2, high strength knruling

3,with film taping device

Thermal break profile knurling machine is the first step of thermal break assembly machine, used for knurling the teeth in slot of aluminum profiles, in order to increasing the friction between aluminum and polyamide strips, increase the final strength of thermal break aluminum profiles.

Two kinds of knurling machine :

| 1 | knurling machine with strip feeding device operation: 1,knurling and strip feeding in first piece of aluminum profiles 2, knurling and strip feeding in second piece of aluminum profiles, also let two pieces of aluminum profiles connect by polyamide strips. |

| 2 | only have knurling function. |

Advantage of thermal break profile knurling machine:

| good quality knurling knife |  |

| Italy motor and speed reducer |  |

| supply touch screen operation design | realize more automation |

| high precision in each parts | make sure the precision under control |

| strong structure | make sure no shaking during running |

Regular thermal break profile knurling machine main parameters, supply customized design:

| Total power | 1.5kw |

| maximum profile size | width 320* height 500mm |

| knurling knife diameter | 80mm |

| speed | 0~70m/min |

| compressed air | 0.6~10Mpa |

| main machine size | L1210*W1310*H1810(mm) |

| weight of machine | Around 1150kgs |