Nylon Thermal Break Profile Extrusion Machine

Nylon thermal break profile extrusion machine main features:

1, easily operation

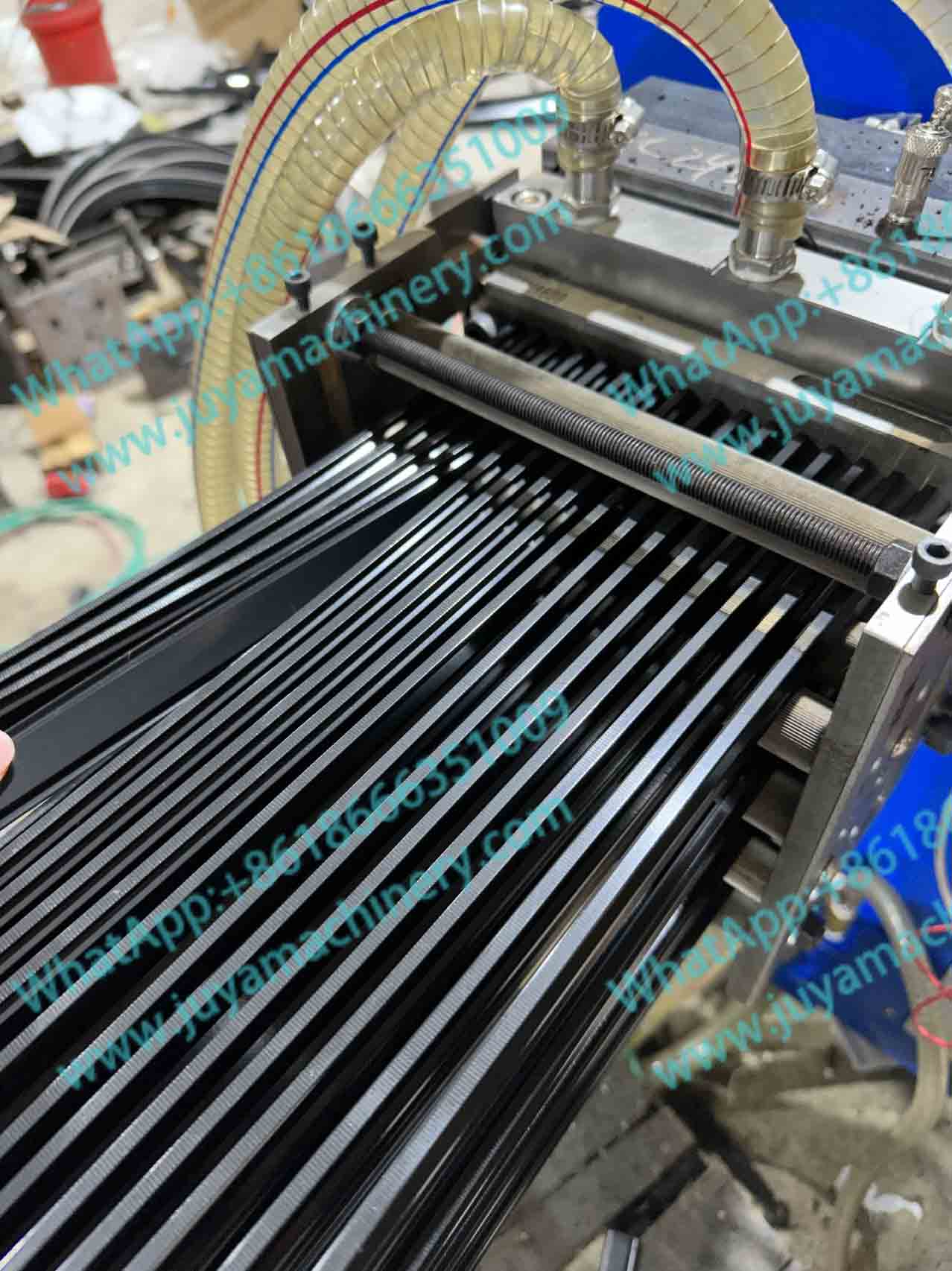

2, easily produce thermal break profile strip

3, complicated thermal break profile is also easily to make

4, special advantage technology

With advantage of easily make variable thermal break profile strips, get a lot of cutsomer in China and all over the world, such as Turkey,Poland, Germany,Russia,Kazakhstan,Canada etc.

From raw material of 25% glass fiber and 75% nylon,finished nylon thermal break profile strips, strip extrusion machine,and thermal break profile strips assembly machine, supply turnkey project.

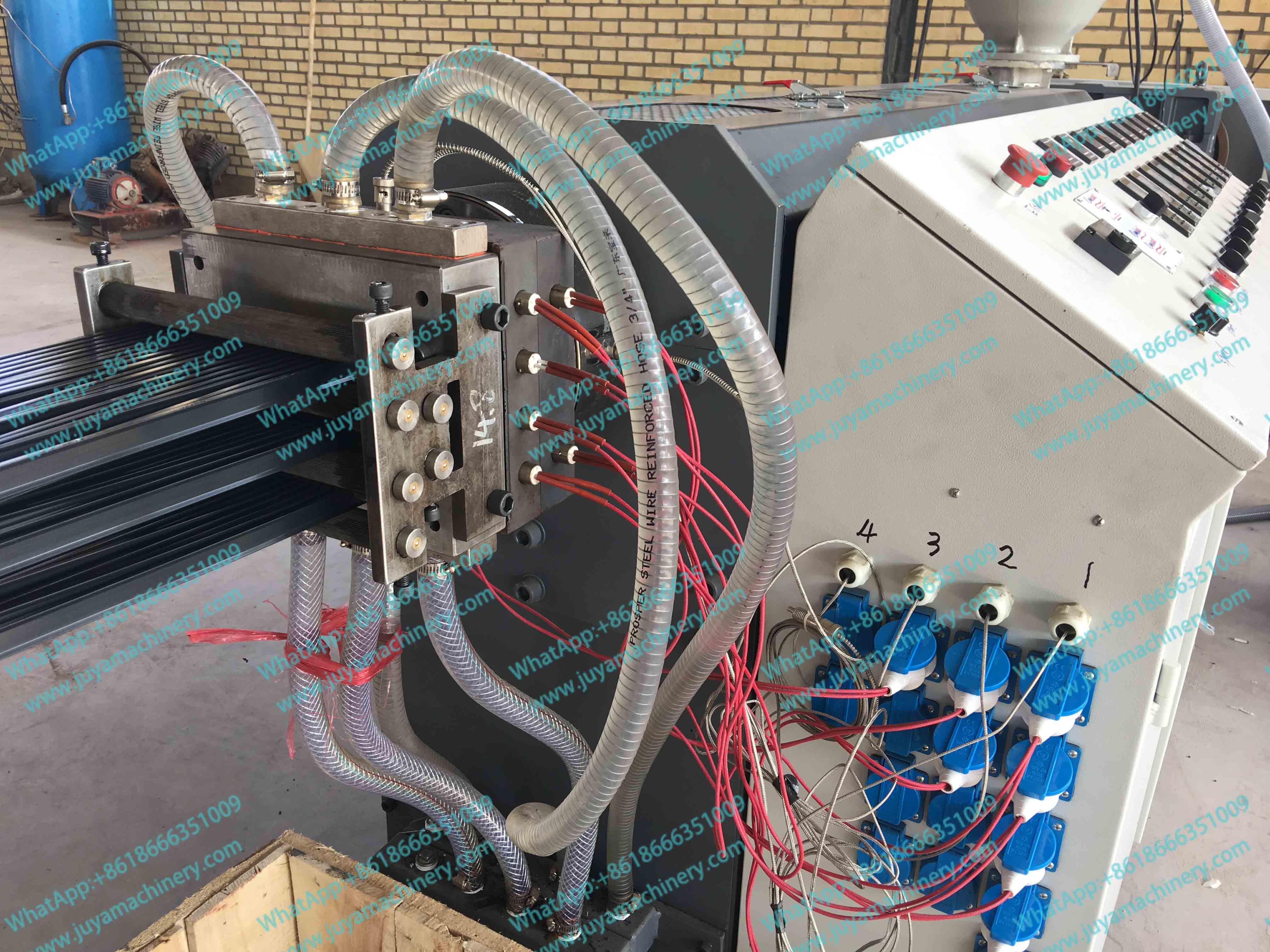

Technical parameters of Nylon thermal break strip extrusion machine:

| extrusion speed | 10~15cm/min(each cavity) |

| cavity quantity | 20~200 pieces |

| screw type | single screw |

| screw material | double metal |

| screw diameters | 70/90 |

| power | 38kw |

| cooling type | circulation water |

Configuration of nylon thermal break extrusion machine:

| 1 | automatic raw material loading |

| 2 | automatic raw material dry machine |

| 3 | automatic extrusion machine |

| 4 | nylon thermal break strip extrusion mould |

| 5 | automatic strip cutting machine |

| 6 | automatic thermal break strip rewinder machine |

Advantage of nylon thermal break strip extrusion machine:

| 1 | easily operate |

| 2 | easily learn |

| 3 | easily to run mould smoothly |

| 4 | online support and site support |

Raw material of nylon thermal break profile is 75% nylon and 25% glass fiber, which have low conductivity function, insert thermal break profile between two pieces of aluminum profile, to make window and door, prohibit hot or cold transfer through aluminum window and doow, play a part in energy saving function,popular used in China, and European countries, more and more popular used in Middle east country.

Direct manufacturer, fast delivery,fast respond after sales service,good price of value.