Extrusion Lines For Thermal Breaking Profiles

Extrusion Lines For Thermal Breaking Profiles:

1,fast delivery

2, direct manufacturer

3, supply turnkey project

4,good value of price

Supply turnkey project from raw material of thermal breaking profile to finished thermal breaking profiles:

raw material of thermal breaking profiles 1,25% glass fiber and 75% nylon 2,two kinds of raw material: powder coating allowed powder coating not allowed | |

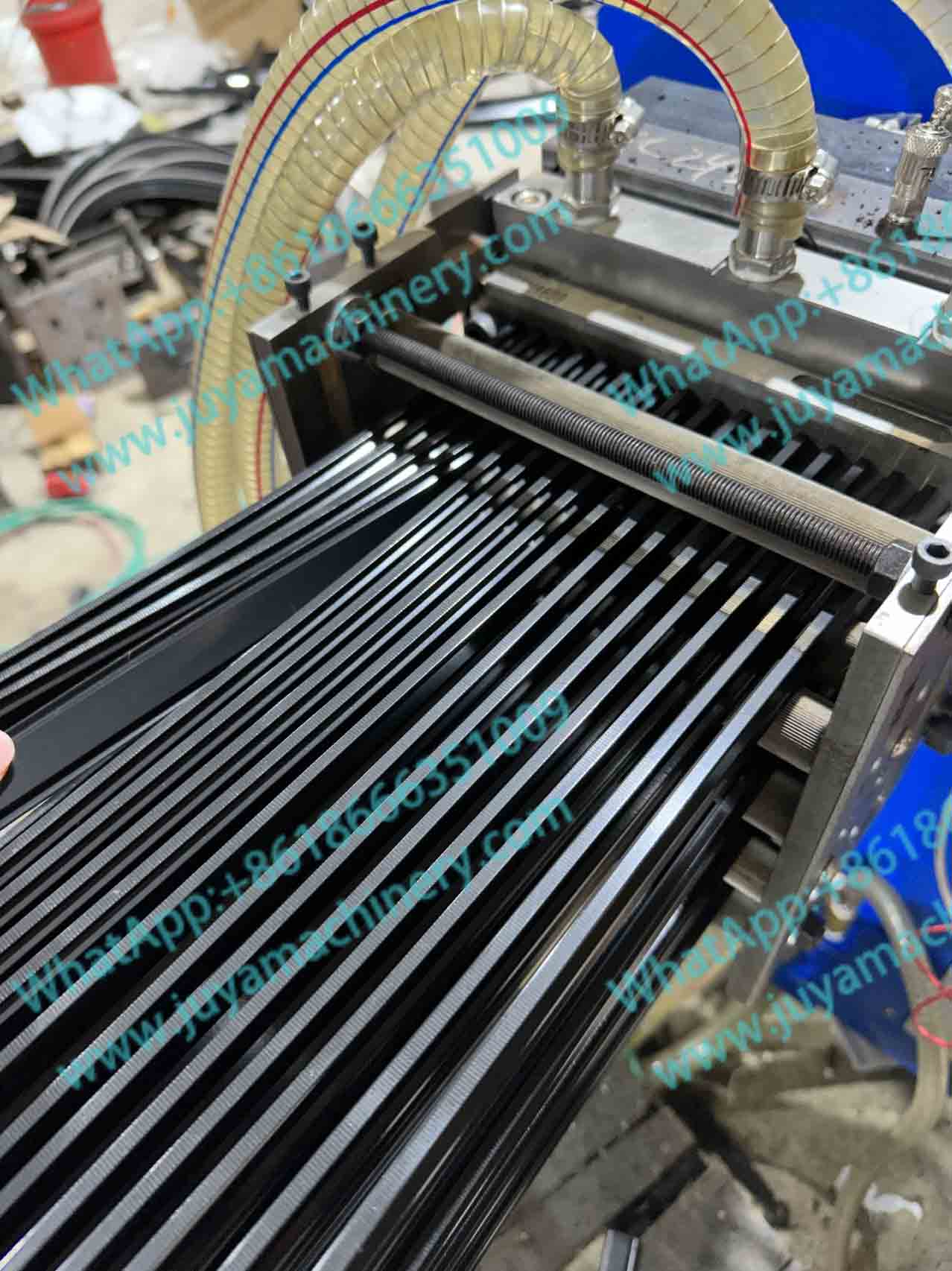

finished thermal breaking profiles: 1, all kinds of shape , I,C,CT,hollow profiles 2, powder coating allowed 3,powder coating not allowed types also available |  |

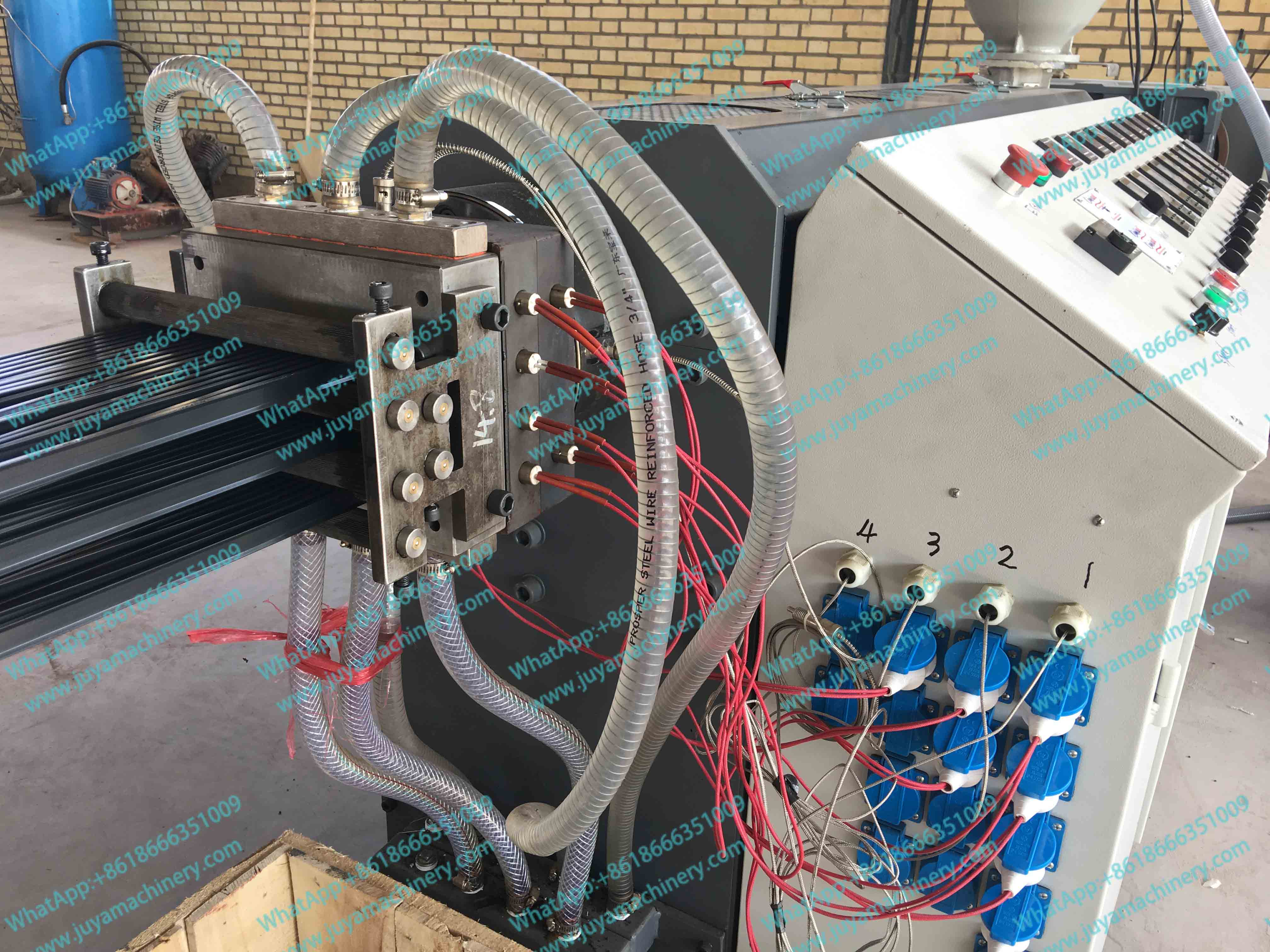

thermal breaking profiles extrusion lines: 1,automatic raw material loading 2,automatic raw material drying 3,thermal breaking profiles mould 4, automatic profiles cutting 5, automatic profiles rewinder 6,circulation water cooling |  |

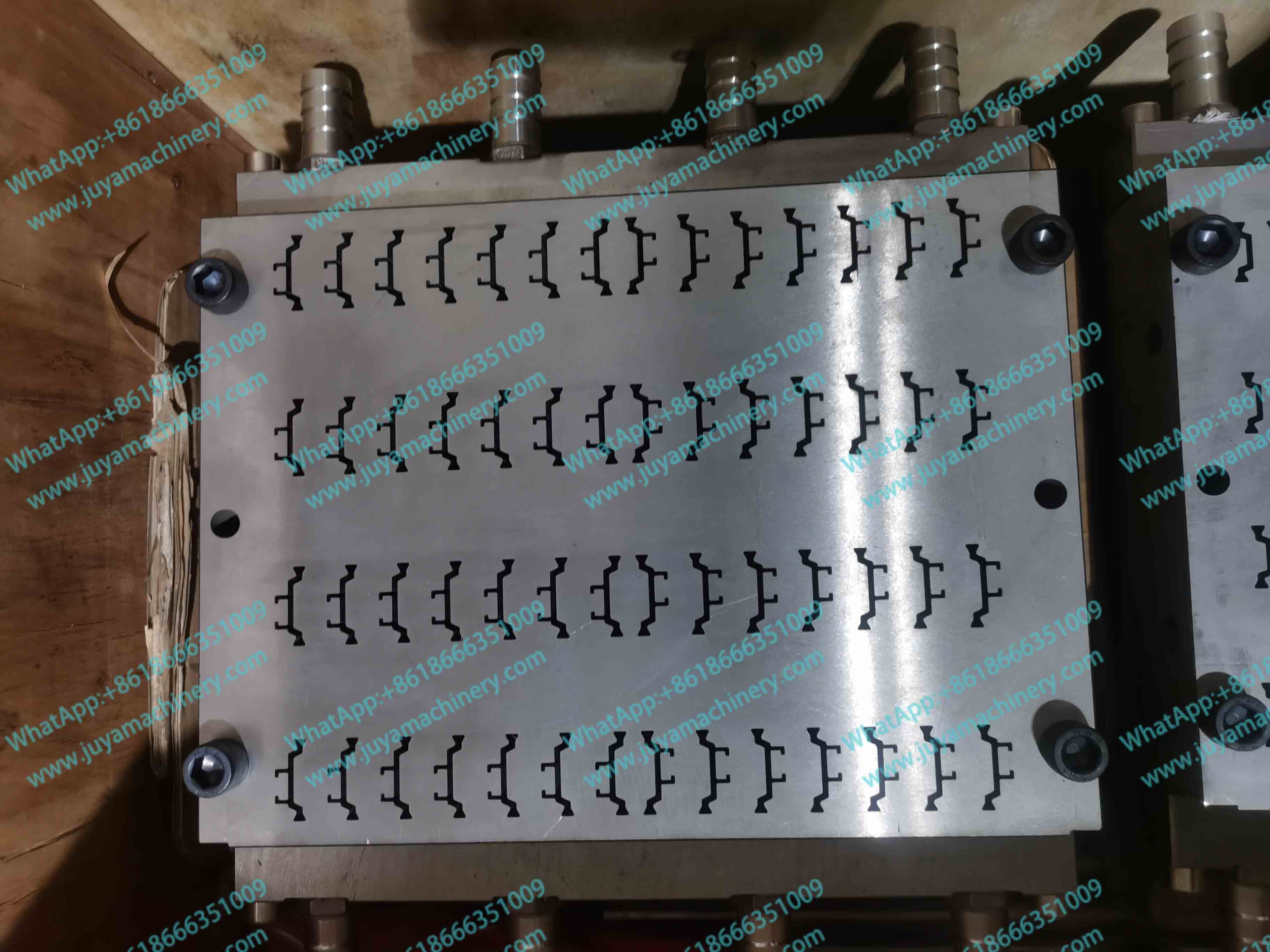

thermal breaking profiles mould: 1,all kinds of thermal breaking profiles moulds are all available 2, hollow type is easy to extrude 3,easy operation 4, 20~200 cavities in one mould 5, combine shape in one mould 6,special technology for making extrusion |  |

thermal breaking profiles rewinder machine: 1,collect finished thermal breaking profiles as rolling packing 2,automatic meter counter. |  |

thermal breaking profiles automatic cutting: 1,cutting multiple thermal breaking profiles automatically 2, with thermal breaking profiles table |  |

Company advantage:

| 1 | direct manufacturer |

| 2 | professional manufacturer with 20 years experience |

| 3 | special technology to make easily thermal breaking profiles extrusion |

| 4 | widely used in China mainland |

| 5 | export to many countries, with good reputation, such as Germany, Canada,Turkey,Poland etc. |

Main information of thermal breaking profiles extrusion lines:

| power | 38kw |

| extrusion speed | 10~15cm/min(each cavity) |

| screw type | single screw |

| screw material | double metal |

| screw diameter | 70/90mm |

| mould material | H13 |

| main electrical parts | Omron and Schneider |

Cooperation condition:

| Payment terms | 50% advance payment,50% paid before delivery; T/T or LC at sight |

| Delivery time | 15~35 days |

| Technical support | online support; site support; customer send engineer to our factory to learn running extrusion lines |

| Warranty | one machine: one year excluding easy wearing parts. |